Cage Nuts

Installation

How do I use cage nuts?

This video is about cage nuts and describes how to install and remove them, and how to identify if your product includes cage nuts.

You may have heard of cage nuts and wondered what they are and how they are used. Today we are going to discuss cage nuts and show you some of their advantages and uses.

Cage nuts are used to mount IT equipment in server racks, such as the Server racks compatible with cage nuts can be easily identified by the square holes the cage nuts use. Cage nuts are great for protecting your equipmUent from stripped threads and allow for convenient mounting of your server rack equipment.

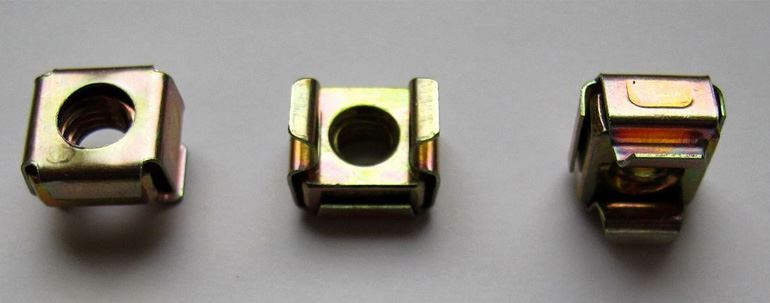

A cage nut houses a standard nut in a cage with a spring. The cage has two wings that can be pinched together to allow the cage nut to be inserted into a square hole. The wings are then released to hold the cage nut in place. Cage nuts come in many sizes but M5 and M6 cage nuts are mainly used in IT environments. M6 is a heavier, more robust cage nut that M5.

Let’s take a look at mounting a Cage Nut on a rail in the

In some situations, you may be advised to use a slot screwdriver to help install cage nut. However, you will find it much easier to use a cage nut mounting tool.

To install a cage nut, use your tool to attach one of the wings from the cage nut. Keep the pressure on the cage nut with your finger and then attach the other wing. The cage nut is now ready for the mounting screw.

To uninstall a cage nut, use your tool to release the cage nut wing on one side and then the other side.

You can check to see if your StarTech.com product includes cage nuts by navigating to the StarTech.com website, searching for the product, and checking the Technical Specifications tab under the heading What’s in the Box.

A cage nut or caged nut (also called a captive or clip nut) consists of a (usually square) nut in a spring steel cage which wraps around the nut. The cage has two wings that when compressed allow the cage to be inserted into the square holes, for example, in the mounting rails of equipment racks. When the wings are released, they hold the nut in position behind the hole. Cage nuts conforming to this description were patented in 1952 and 1953.[1][2] This design requires insertion tools to install the cage nut into the hole. Newer designs featuring a squeeze-and-release tab allow for tool-less installation.

The square-hole cage nut can be used wherever a square hole can be punched. An older type of captive-nut uses a spring clip that holds the nut and slides on the edge of a thin sheet. While this type of cage nut can only position the nut a fixed distance from the edge of a thin plate, it works equally well with square and round holes. A patent for such a nut was granted in 1946.

Using cage nuts provides several benefits over threaded holes. It permits a range of choice of nut and bolts size (e.g. metric vs imperial) in the field, long after the equipment has been manufactured. Second, if a screw is over-tightened, the nut can be replaced, unlike a pre-threaded hole, where a hole with stripped threads becomes unusable. Third, cage nut are easy to use on materials too thin or soft to be threaded.

The nut is usually slightly loose in the cage to allow for minor adjustments in alignment. This reduces the likelihood that the threads will be stripped during equipment installation and removal. The dimensions of the spring steel clip determines thickness of the panel to which the nut may be clipped. In the case of square-hole cage nuts, the clip dimensions determine the range of hole sizes to which the clip will securely hold the nut. In the case of slide-on cage nut, the clip dimensions determine the distance from the panel edge to the hole.

A common use for cage nuts is to mount equipment in square-holed 19-inch racks (the most common type), with 0.375 inches (9.5 mm) square-hole size. There are four common sizes: UNF 10–32 and, to a lesser extent, UNC 12–24 are generally used in the United States; elsewhere, M5 (5 mm outside diameter and 0.8 mm pitch) for light and medium equipment and M6 for heavier equipment, such as servers.

Although some modern rack-mount equipment has bolt-free mounting compatible with square-hole racks, many rack-mount components are generally mounted with cage nut.

Removing Cage Nut.

Device installation might require the removal or moving of the rear-pane cage nuts. If you need to move the cage nuts, follow this procedure to move them and then go to (below) ‘Installing Cage Nut’. to install them in the correct position.

- Hold the cage nut in place and compress the cage-nut clip with a flat screwdriver blade.

- With the cage nut-clip compressed, push the cage nut-clip out of the square hole.

- Release the screwdriver pressure on the clip. The cage nut is now loose and can be removed from the square hole.

Installing Cage Nuts: The nuts go toward the inside of the . Make sure you install all the cage nuts at the same level on the mounting rails.

- Hook one side of the cage-nut clip into the rack-mounting-rail square hole.

- Hold the cage nut in place and compress the cage-nut clip with a flat screwdriver blade.

- With the cage-nut clip compressed, push the cage-nut clip into the square hole.

- Release the screwdriver pressure on the clip. The cage nut is now locked in the square hole.

Cage Nuts Manufacturers in India

Cage Nuts manufacturers in India. Leading suppliers dealers in Mumbai Chennai Bangalore Ludhiana Delhi Coimbatore Pune Rajkot Ahmedabad Kolkata Hyderabad Gujarat and many more places. Sachiya Steel International manufacturing and exporting high quality Cage Nuts Fasteners worldwide. We are India’s largest Cage Nuts Exporter, exporting to more than 85 countries. We are known as Cage Nuts Manufacturers and Exporters due to exporting and manufacturing on a large scale.

Cage Nuts Manufacturers in India: Cage Nuts Specifications –

We at Sachiya Steel International manufacture a wide variety of Nuts. There is a different types of Nuts used for different needs. Nuts are used with Bolts. Our Nuts are available in different sizes, grades and shapes. Sachiya Steel International manufactures and exports high-quality industrial Nuts. We are Exporters of the following Nuts –Hex Nuts, Heavy Hex Nuts, Lock Nuts, Nylock Nuts, Nylock Seld Locking Nuts, Flange Nuts, Rivet Nuts, Cage Nuts, Dome Nuts, Square Nuts and more. We are a well known and India’s leading Industrial Cage Nuts Exporters in Mumbai.

| Cage Nuts sizes available | |||

|---|---|---|---|

| 3/8″-16 Zinc Finish Grade 5 Finished Cage Nuts | 1/2″-13 Zinc Finish Grade 5 Finished Cage Nuts | 5/16″-18 Zinc Finish Grade 5 Finished Cage Nuts | 3/4″-10 Zinc Finish Grade 5 Finished Cage Nuts |

| 5/8″-11 Yellow Zinc Finish Grade 8 Finished Cage Nuts | 1/4″-20 Zinc Finish Grade 5 Finished Cage Nuts | 5/8″-11 Zinc Finish Grade 5 Finished Cage Nuts | 3/8″-16 Yellow Zinc Finish Grade 8 Finished Cage Nuts |

| 3/4″-10 Yellow Zinc Finish Grade 8 Finished Cage Nuts | 1/2″-13 Yellow Zinc Fi nish Grade 8 Finished Cage Nuts | 3/8″-16 Zinc Finish Grade A Finished Cage Nuts | 1/4″-20 Zinc Finish Grade A Finished Cage Nuts |

| 1/2″-13 Zinc Finish Grade A Finished Cage Nuts | 1/4″-20 18-8 Stainless Steel Finished Cage Nuts | 1/2″-13 18-8 Stainless Steel Finished Cage Nuts | 1/4″-20 Yellow Zinc Finish Grade 8 Finished Cage Nuts |

| 5/16″-18 Zinc Finish Grade A Finished Cage Nuts | 5/16″-18 Yellow Zinc Finish Grade 8 Finished Cage Nuts | 1″-8 Yellow Zinc Finish Grade 8 Finished Cage Nuts | 5/8″-11 18-8 Stainless Steel Finished Cage Nuts |

| 5/8″-11 Zinc Finish Grade A Finished Cage Nuts | 1″-8 Zinc Finish Grade 5 Finished Cage Nuts | 7/16″-14 Zinc Finish Grade 5 Finished Cage Nuts | 7/16″-14 Yellow Zinc Finish Grade 8 Finished Cage Nuts |

| 3/4″-10 Zinc Finish Grade A Finished Cage Nuts | |||

| Specification | ||

|---|---|---|

| Material | Standards | Grades |

| Nickel Alloy | ASTM / ASME SB 160 / 164 / 425 / 166 / 446 / 574 / 472 | UNS 2200 (NICKEL 200) / UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400), UNS 8825 (INCONEL 825), UNS 6600 (INCONEL 600) / UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276), UNS 8020 (ALLOY 20 / 20 CB 3) |

| Stainless Steel | ASTM / ASME A/SA 193 / 194 | B 8 (304), B 8C (SS 347), B 8M (SS 316), B 8 T (SS 321), A 2, A 4 |

| Alloy Steel | ASTM / ASME A/SA 193 / 194 GR | B 6, B 7/ B 7M, B 16, 2, 2HM, 2H, GR 6, B 7, B 7M |

| Duplex Steel | UNS NO. S 31803, S 32205 | |

| Nonmetallic Materials: | Acrylic, Kel-F, Lexan, Polypropylene, Poly Vinyl Chloride, Teflon, Zytel 31, 101, 105 | |

| High-Temp Alloys | Discaloy, 19-9 DL, 16-25-6, A286, Titanium, Nimonic 80, Mulitmet, Haynes 25, Greek Ascalloy, Unitemp 252, Udimet 500, Rene 41, Inco 700, Inco 901, Hastelloy X, 235, Waspaloy, RA 330 | |

| Copper Base Alloys | Copper, Brasses: Yellow, Free-cut, Red, Naval, Bronze: Commercial, Phosphor, Silicon A & B, Aluminum, Silicon-Aluminum, Manganese, Ampco Alloys, Munitz Metal, Cupro-Nicles | |

| Aluminum Alloys: | 1100, 2011, 2014, 2017, 2024, 3003, 5052, 6053, 6061, 7075 | |

Cage Nuts Manufacturers in India: About Cage Nuts Fasteners –

Cage Nuts are a type of fastener with a threaded hole. Cage Nuts are almost always used in conjunction with a mating bolt to fasten multiple parts together. The two partners are kept together by a combination of their threads’ friction (with slight elastic deformation), a slight stretching of the bolt, and compression of the parts to be held together. Today Cage Nuts are used when a maximum amount of torque and grip is needed for a given size. Sachiya Steel International manufactures and exports high-quality Cage Nuts.

Cage Nuts Manufacturers in India: Industrial Cage Nuts –

- Oil & Gas Industries

- Nuclear Energy Sector

- Petroleum Industries

- Chemical Industry

- Defence Industry

- Aerospace Industry

We are leading Exporters of Cage Nuts in more than 85 Countries worldwide. We export to countries like Kuwait, Dubai, China, Bahrain, Oman, Saudi Arabia, Qatar, Iran, UAE, Brazil, Mexico and more.

Cage Nuts Manufacturers in India: Cage Nuts Finishes –

- Plain Finish Cage Nuts: Cage Nuts with No Coating.

- Zinc Plated Cage Nuts: Cage Nuts Coated with Zinc.

- Zinc and Chromate Cage Nuts: Silvery and offers resistant to corrosion for Cage Nuts.

- Zinc and Yellow Chromate Cage Nuts: Offers better resistant to corrosion to Cage Nuts than Chromate.

- Hot Dipped Galvanized(HDG) Cage Nuts: Offers superior resistant to corrosion due to the dipping of Cage Nuts in the molten zinc.

Client Project Report

| Product supplied | City |

|---|---|

| Cage Nuts in Oil Plant | Rajkot, Gujarat |

| All types of Cage Nuts supply | Ahmedabad, Gujarat |

| Stainless Steel Cage Nuts | Nagpur, Maharashtra |

| Carbon Steel Cage Nuts | New Delhi, Delhi NCR |